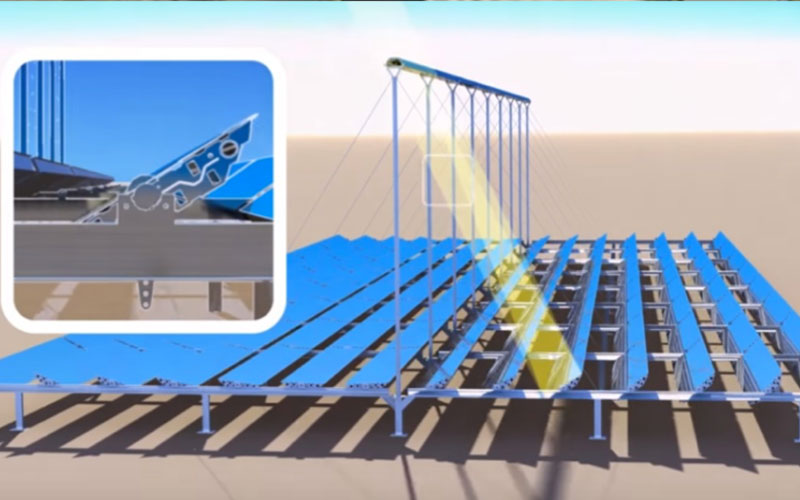

Stamped metal parts for the

Solar Energy

We offer an integral service; from engineering and manufacturing of dies and prototypes to industrialization and manufacturing of the final product.

STAMPING / WELDING / ASSEMBLING

Download our catalog to see how we can help you.

Company

Committed to quality and continuous improvement

We are dedicated to the manufacture and design of stamped metal parts, welding and assembly of sub-assemblies. We are specialists in offering an integral service that ranges from the design and manufacture of dies, industrialization and fine-tuning to the manufacture of the final product.

Flexibility and adaptation

Your requirements are our guidelines when developing each job. We adapt 100% to you.

Qualified staff

Our team has extensive experience and specialization in the stamping sector. This makes our pieces of high quality.

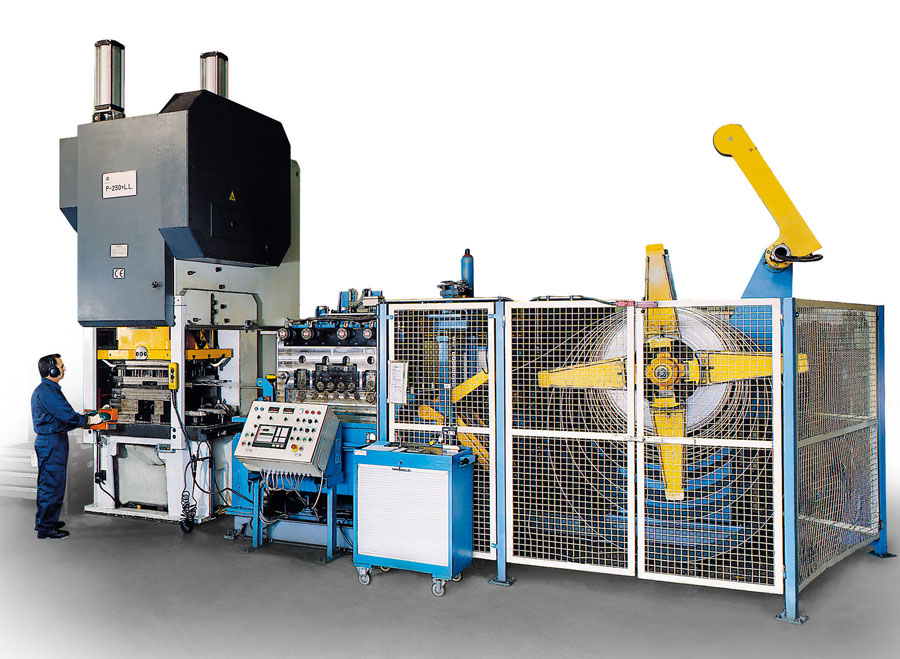

Large machine park

We have the best technology. We have a park of machines ranging from 400tn to 1800tn.

Machinery

We offer you the expected result

We have a large machinery park with mechanical and hydraulic presses for progressive productions of up to 1,800 tonnes and a prepared human team that allows us to stay at the forefront of a highly competitive sector offering our clients great technical possibilities.

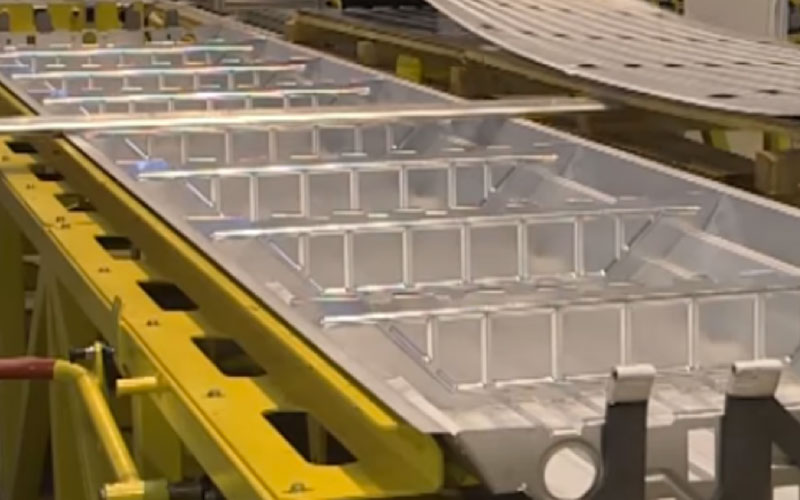

Products

Proud of what we do

At Larreno we can manufacture stamped metal parts with a high technical requirement from small to medium-large size..

We manufacture with different kind of materials. Specialized in Magnelis of different qualities.

We work with thickness form 0.3mm to 8mm

Please contact us if you need a quote,

Certificaciones

Cumplimos con tu standard de calidad

Our projects, our best guarantee

We have participated in the following projects: Génesis, Extresol, Noor Ouarzazate, Kathu y eLLO.

Tell us about your project

If you have a project and need a metal part, write to us explaining what you need and we will contact you offering a solution.

Polígono Industrial BOROA, 17

48340 AMOREBIETA-ETXANO (SPAIN)

Press FAGOR LE4-1000-5000-2200 double-sided press and effect LINK DRIVE

- Nominal force, 10.000 kn

- Bolster size, 5.000 x 2.200 mm

- Chariot size, 5.000 x 2.200 mm

- Race, 600 mm

- Distance between bolster and chariot, low course, high regulation, 1200 mm

- Chariot regulation, 500 mm

LASA COMPACT FEEDING LINE

- Maximum bandwidth, 1.550 mm

- Thickness, 0,5 ÷ 9,5 mm

- Maximum coil weight, 15.000 kg

- Maximum advance, 0,99999 mm

- Precision, ± 0,1 mm

- Top speed, 60 m/min

- Maximum cadence, 90 m/min

- Max outside diameter, 1.800 mm

Press CLEARING LE2-800-4200-1800

- Nominal force, 8.000 Kn

- Bolster size, 4.200 x 1.800 mm

- Chariot size, 4.200 x 1.800 mm

- Race, 800 mm

- Distance between bolster and chariot, low course, high regulation, 1.000 mm

- Chariot regulation, 400 mm

PERFECT FEED LINE

- Maximum bandwidth, 2.000 mm

- Thickness, 0,5 ÷ 9 mm

- Maximum coil weight, 25.000 kg

- Maximum advance, 0,99999 mm

- Precision ± 0,1 mm

- Top speed, 80 m/min

- Max outside diameter, 1.800 mm

Press ARISA S-2-630-300-150-F-S

- Nominal force, 6.300 kn

- Bolster size, 3.000 x 1.500 mm

- Chariot size, 3.000 x 1.500 mm

- Variable race, 25 ÷ 300 mm

- Distance between bolster and chariot, low course, high regulation, 700 mm

- Chariot regulation, 175 mm

LASA COMPACT FEEDING LINE

- Maximum bandwidth, 900 mm

- Thickness, 0,5 ÷ 9 mm

- Maximum coil weight, 10.000 kg

- Maximum advance, 0,99999 mm

- Precision, ± 0,1 mm

- Top speed, 80 m/min

- Max outside diameter, 1.700 mm

Press FAGOR EM2-400-2150-1060

- Nominal force, 4.000 kn

- Bolster size, 2.200 x 1.100 mm

- Chariot size, 2.700 x 1.100 mm

- Race, 700 mm

- Distance between bolster and chariot, low course, high regulation, 870 mm

- Chariot regulation, 400 mm

LASA COMPACT FEEDING LINE HDC 20CNE GHV

- Maximum bandwidth, 500 mm

- Thickness, 0,5 ÷ 4 mm

- Maximum coil weight, 5.000 kg

- Maximum advance, 0,99999 mm

- Precision, ± 0,1 mm

- Max outside diameter, 1.200 mm

PRESS FAGOR P.S.R. 400 DOUBLE SIDED

- Nominal force, 4.000 kn

- Bolster size, 1.500 x 1.000 mm

- Chariot size, 1.350 x 800 mm

- Race, 20 ÷ 250 mm

- Distance between bolster and chariot, low course, high regulation, 460 mm

- Chariot regulation, 130 mm

LASA COMPACT FEEDING LINE

- Maximum bandwidth, 500 mm

- Thickness, 0,5 ÷ 8 mm

- Maximum coil weight, 4.000 kg

- Maximum advance, 0,99999 mm

- Precision ± 0,1 mm

- Max speed, 80 m/min

- Max outside diameter, 1.800 mm

PRESS DELTECO P.S.R. 250

- Nominal force, 2.500 kn

- Bolster size, 800 mm

- Variable race, 20 ÷ 250 mm

- Distance between bolster and chariot, low course, high regulation, 380 mm

- Chariot regulation, 150 mm

LASA COMPACT FEEDING LINE DIMECO

- Maximum bandwidth, 1.000 mm

- Thickness, 0,5 ÷ 9 mm

- Maximum coil weight, 10.000 kg

- Maximum advance, 0,99999 mm

- Precision, ± 0,1 mm

- Max speed, 80 m/min

- Max outside diameter, 1.700 mm

HIDRAULIC PRESS ONAPRES UBe-180-3,25-APS

- Maximum pressing force (adjustable if stepping between 1,500 and 7,000 kn), 18,000 kn

- Adjustable maximum recoil force, 720 kn

- Number of main cylinders, 4

- Number of recoil cylinders, 2

- Bolster size, 3.250 x 2.000 mm

- Maximum opening between bolsters, 2.500 mm

- Maximum adjustable carriage travel, 1.800 mm

- Minimum distance between the carriage and the lower bolster, 700 mm

- Useful step (side), 1.000 mm

- Working height, 200 mm pressure

- Maximum adjustable pressure, 258 bar

- Drive power, 75 kw

- Race, 600 mm

- Distance between bolster and carriage, low course, high regulation, 1,200 mm

- Chariot regulation, 500 mm